In the world of new technology, few things have caught people’s attention like 3D printing. As we move further into the 21st century, its importance keeps growing, especially in construction. Let’s explore the most important things you need to know about 3D printing, from its use in construction to sector expectations!

What is 3D Printing in Construction?

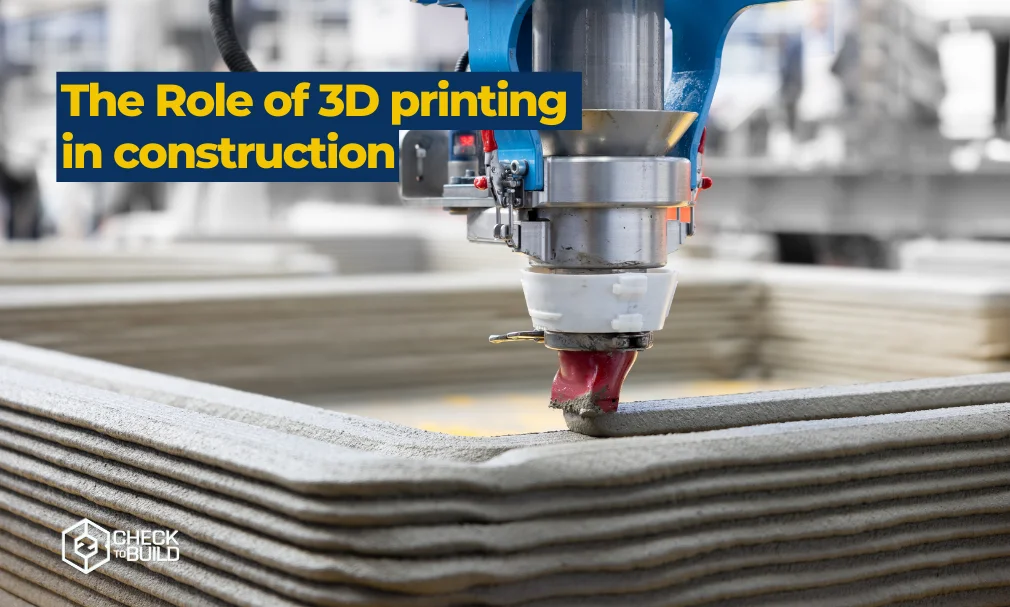

3D printing in construction, also known as additive manufacturing, revolutionizes traditional building methods. It involves the layer-by-layer fabrication of structures using various materials like concrete, polymers, and metals. Unlike conventional construction techniques, 3D printing offers unparalleled flexibility, precision, and sustainability. Architects and engineers can realize complex designs with ease.

Advanced robotics and computer-aided design (CAD) facilitate this innovative process. They enable the seamless translation of digital models into physical structures. 3D printing avoids traditional formwork and molds. Architects gain greater creative freedom while minimizing material wastage. Whether crafting intricate components or fabricating entire buildings, 3D printing’s versatility spans a wide range of applications, both onsite and offsite.

Use of 3D Printers in Construction

That technology is increasingly used in construction to simplify traditional building methods. This technology involves building structures layer by layer using various materials like concrete, polymers, and metals. Unlike traditional construction, 3D printing offers unmatched flexibility, accuracy, and sustainability, making it easier for architects and engineers to bring intricate designs to life.

The use of 3D printing in construction is made possible by advanced robotics and computer-aided design (CAD), which convert digital models into physical structures seamlessly. By avoiding traditional molds and formwork, 3D printing allows architects to express their creativity while minimizing material waste. Whether it’s creating custom components or constructing entire buildings, the versatility of 3D printing extends to various applications, both on-site and off-site.

With the help of CAD or Building Information Modeling (BIM), complex digital models can be transformed into tangible structures using specialized 3D printers designed for construction.

Methods and printed materials

Different techniques, like FDM, SLS, and SLA, offer unique ways to create objects layer by layer. Not every material can be used in these types of processes, although within the limitations, there is a relatively high number of components. The most commonly used materials in these types of prints are Standard concrete, Proprietary concrete mixes, Mortar, Plastic, Metal, and Local natural materials (stone, sand, mud, rice waste, etc). In construction, these methods bring innovation, allowing for the creation of complex structures with detailed precision. These are some of the most popular methods:

- FDM (Fused Deposition Modeling): This method heats and melts filamentous hot-melt material. A computer-controlled nozzle deposits the material layer by layer onto a worktable, forming the desired shape after rapid cooling.

- SLS (Selective Laser Sintering): This technique spreads a layer of powdered material onto a surface and heats it just below its sintering point. A laser beam scans the powder layer according to the object’s cross-sectional profile, causing the powder to sinter and bond with the layer below. The process repeats until the entire model forms.

- SLA (StereoLithography Apparatus): SLA uses liquid photosensitive resin. An ultraviolet laser cures the resin layer by layer according to the machine’s instructions, solidifying it to form each cross-sectional layer. The layers stack to create a 3D object.

- Extrusion: TThis is the most common technique in construction. Material dispenses through nozzles mounted on a robotic arm, gantry system, or crane. It’s versatile and widely used for modeling, prototyping, and production.

- Powder Bonding: This method uses powdered material, either by melting it with a laser (powder bed jetting) or binding it with a liquid agent (binder jetting). It offers high precision and suits intricate prints.

- Spray: An independent robot sprays pressurized construction material selectively to shape the desired object layer by layer. Researchers are studying it for various construction elements like façades or ceiling embellishments.

- Sand Layers: This technique releases layers of sand and bonds them with a binding agent. It suits creating small structures or components and requires less specialized equipment.

What are the benefits?

The integration of 3D printing into the construction industry brings numerous benefits throughout the value chain:

- Time Reduction: Projects that traditionally took a long time can now be completed much faster, with completion times reduced by up to 70%. This not only increases productivity but also allows construction firms to be more responsive to demand.

- Cost-effectiveness and Sustainability: 3D printing minimizes material wastage and streamlines procurement processes, resulting in a more sustainable and cost-effective approach to construction. By using resources more precisely, it reduces environmental impact and optimizes expenditure.

- Safety: Prioritizing worker well-being, 3D printing reduces the occupational hazards associated with traditional construction practices. By automating labor-intensive tasks, it significantly reduces the risk of on-site injuries.

- Design Flexibility: The iterative nature of 3D printing enables real-time customization, accommodating last-minute design changes without slowing down progress. This unmatched flexibility empowers architects to realize their creative vision with unparalleled fidelity.

- Reduction of Human Error: Through the automation inherent in 3D printing technology, the likelihood of human error, injuries, or fatalities is greatly minimized, creating a safer working environment.

The bright future of 3D printing

The future of 3D printing in construction holds significant promise, akin to transformative innovations seen in other industries. Despite the ongoing integration process, the potential advantages, such as cost savings, time efficiency, and environmental benefits, loom large. Builders are increasingly exploring the use of computer-generated, three-dimensional materials, fostering creativity and potentially yielding unprecedented building designs for both commercial and residential purposes.

Throughout history, advancements in construction methods have continuously evolved, with 3D construction printing representing the latest leap forward. This presents ample opportunity for industry professionals to leverage creativity and embrace these technological advancements.

While current 3D printing technology may not yet be suitable for constructing towering skyscrapers due to limitations in printer strength and materials, ongoing technological improvements offer promising prospects. Some companies have already announced plans to utilize 3D printing for skyscraper construction, underscoring its potential viability.

.