SITE-CAST ELEMENTS INSPECTION

CHECKTOBUILD & ACERTA STORY OF SUCCESS

Time to take

decisions

From when the manager went to site to take the point cloud until available results

Costs saved

Estimated cost savings of rework to correct every stair of the project in case all were deviated. $730 per element

Increase in

productivity

Estimated productivity upgrade after subtract spent hours on the same inspection with traditional methods

About the project

Location: Madrid, Spain.

Industry: Office building

Work phase: Above Ground – Structure

Data capture method: iPad Pro (Sitescape)

Size: 232737.27 ft2

Project value: $16.5M

The problem

Casting errors during the structural phase, also known as “site cast element” mistakes, can result in substantial rework expenses. These errors are often caused by misaligned formwork, leading to deviations from the design. Fortunately, these costly mistakes are avoidable through the adoption of advanced technological tools. Implementing thorough formwork inspections can significantly reduce project risks and improve accuracy.

3D models and point cloud inspections for improved accuracy

Operation process & scope

To ensure precise concrete pouring, site managers used a combination of 3D models and point cloud technology during the inspection process. Here’s how the operation was conducted:

- Quality testing: Evaluated the quality of the point cloud, ensuring it accurately captured the concrete formwork before pouring.

- Model uploads: Uploaded BIM models and point clouds for on-site inspection execution.

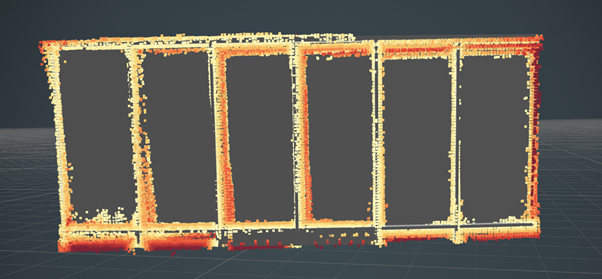

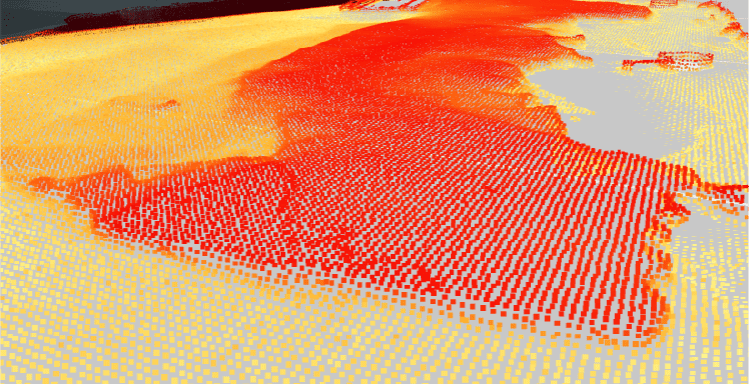

- Heatmap analysis: Used heatmaps on the point cloud to identify deviated areas by switching models from solid to wireframe view.

- Stakeholder collaboration: Shared inspection results with stakeholders to determine corrective actions.

This process ensures greater precision, reduces risk, and provides actionable insights before and after concrete pouring.

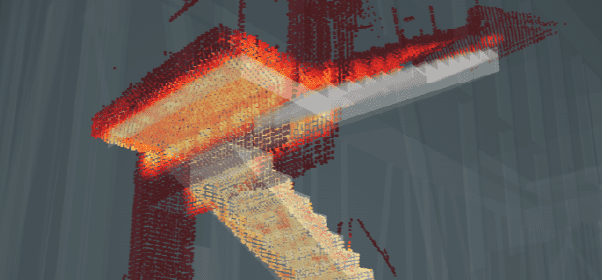

1st INSPECTION RESULTS

At the moment of the operation the element’s concrete wasn’t completely poured. Thus, the system was able to confirm the formwork alignment on the constructed element and the remaining part to pour.

- The system has made a very good comparison of the stairs in formwork, without having finished pouring all the concrete. Actually, it is evident that the edges of the steps are detected as being part of the formwork and not the model, but the already poured concrete is perfectly flat.

- Something similar happens around the side corners of the stairs, where we can observe that the biggest difference between the point cloud and model is in the protruding formwork elements, nevertheless the percentage estimated to be inside of tolerance (which we call “Similarity Percentage”) is of around 97%.

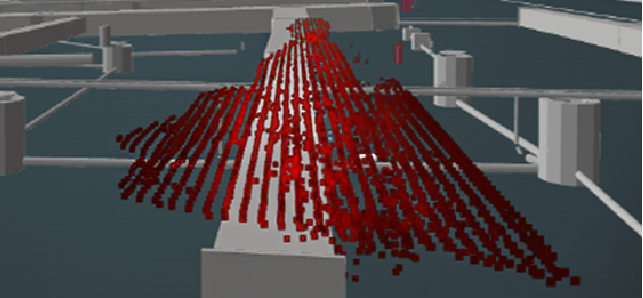

2nd INSPECTION RESULTS

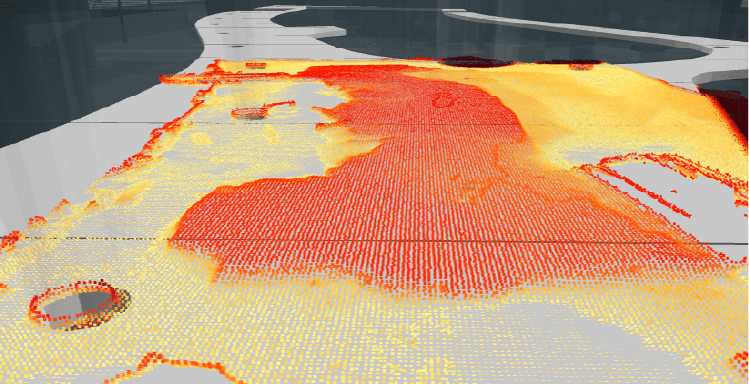

After the concrete pouring was completed, a second inspection revealed some deviations:

- The second section of the stairs had a higher inclination than in the original model.

- The misaligned area would result in an additional 40.28 ft³ of concrete, incurring extra costs.

- The similarity percentage dropped to 61%, showing significant discrepancies compared to the first inspection.

By conducting the inspection post-pouring, misalignments that could have been corrected earlier were identified too late, emphasizing the importance of pre-pouring inspections.

Conclusion

The inspections demonstrated that CHECKTOBUILD’s C2B Platform offers the same accuracy as traditional reality capture techniques while significantly reducing the time needed for analysis and decision-making.

- First Inspection: Allowed the team to correct formwork alignment before pouring, ensuring the structure met the design specifications.

- Second Inspection: Highlighted the cost and time implications of uncorrected deviations, which could have been avoided with earlier inspections.

Key takeaway: Early formwork inspections using the C2B Platform lead to higher accuracy, fewer errors, and optimized project costs. Advanced technology like this is essential for improving construction quality and reducing risk in modern projects.

Do you want access to the full cases in PDF?

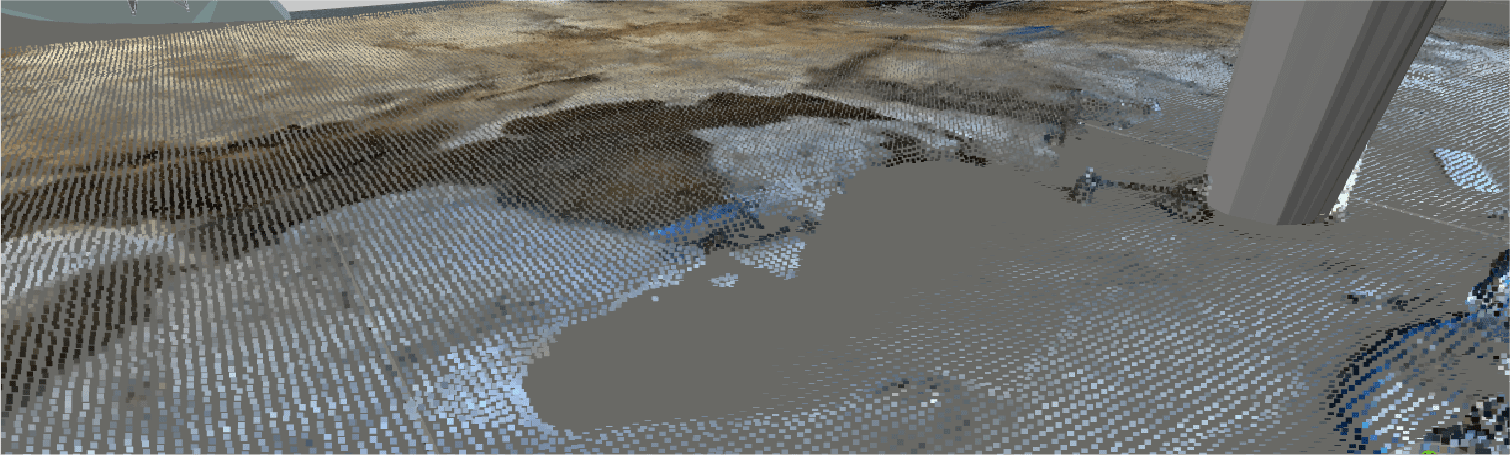

STRUCTURAL ELEMENTS LEVELING INSPECTION

Correct leveling of elements in the construction process requires many hours of work by highly qualified personnel, representing a high cost of multiple revisions, before and after finding any deviation.

PREFABRICATED CURTAIN WALL INSTALLMENT

When using prefabricated modules for construction the Innovative building designs may represent cost overruns if the prefabricated modules are not correctly placed.

WATER PIPES INSTALLATION INSPECTION

Pipe installation requires a post review to verify proper placement. To guarantee the precise level of these elements, will represent the fluid performance of the entire aqueduct and sewage system.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.