WATER PIPES INSTALLATION

CHECKTOBUILD & ACERTA STORY OF SUCCESS

Time to take

decisions

From when the manager went to site to take the point cloud until available results

Costs saved

Estimated cost savings of spent time by the architect to update BIM model to match and operator to correct the error, in case all 36,909 ft of water pipes were deviated

Increase in

productivity

Estimated productivity upgrade after subtract spent hours on the same inspection with traditional methods

About the project

Location: Madrid, Spain.

Industry: Office building

Work phase: Above Ground – Structure

Data capture method: iPad Pro (Sitescape)

Size: 232737.27 ft2

Project value: $16.5M

The problem

Ensuring the ‘quality control of water pipes installation’ is a critical step in any project. This post-installation review process is essential to confirm proper placement, as it directly impacts the overall performance of aqueducts and sewage systems. Evaluating alignment and facility adaptation after installation is crucial during this project phase, helping to determine personnel programming costs.

Operation process & scope

Most pipe facilities in this project are executed by highly qualified personnel to prevent errors. Even so, the site manager expected to:

1. Test the quality of the As-built model for construction inspection

2. Upload models (BIM & POINT CLOUD) to execute the inspection on-site

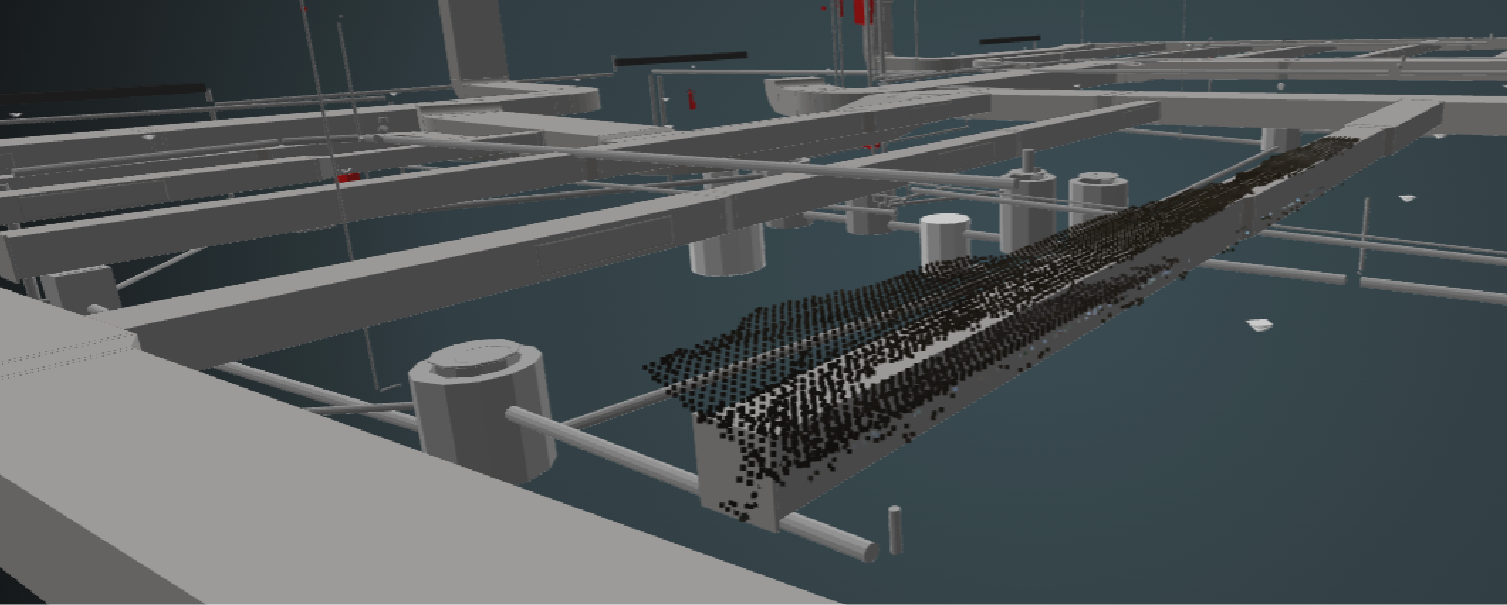

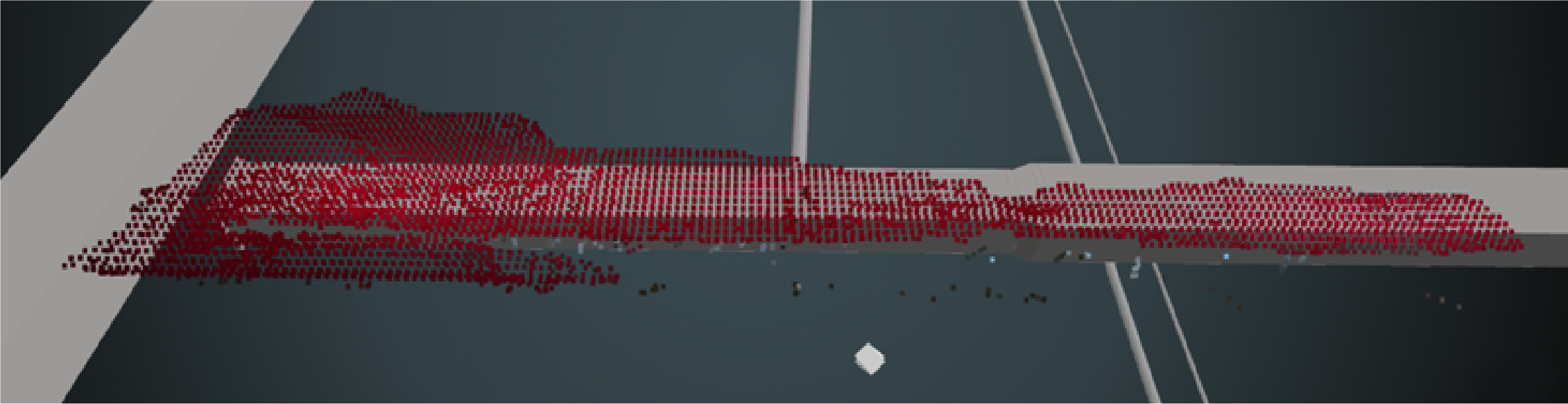

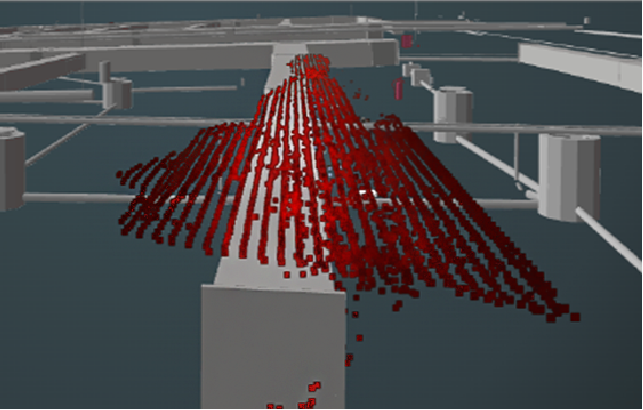

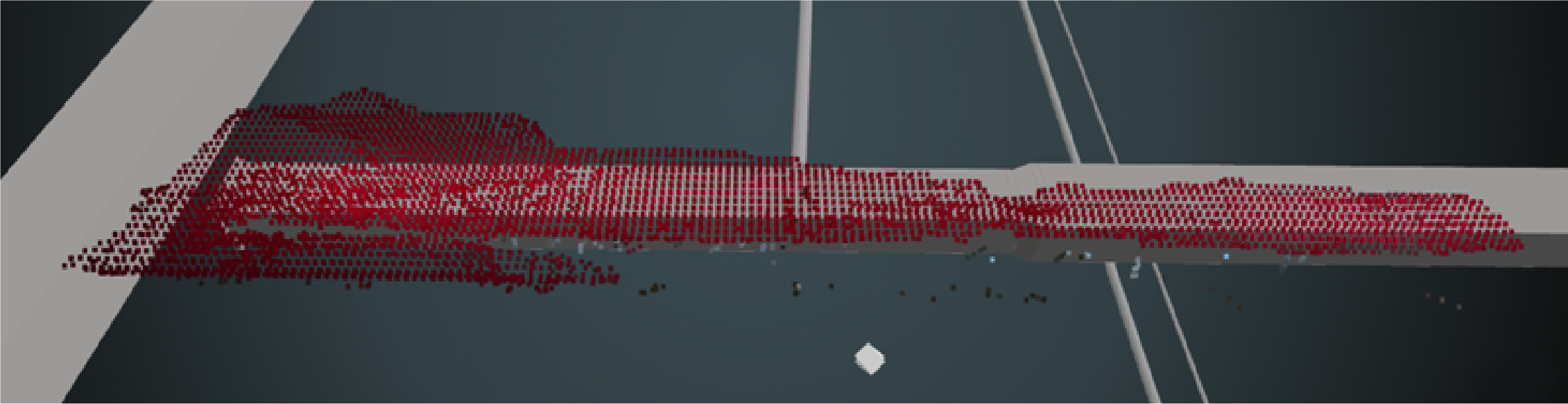

3. After having results and activate the heat map in the point cloud to see is the elements are properly installed and aligned to the model

4. Share the inspection to the stakeholders

RESULTS

Correct updating of the BIM model of a Construction project during execution time is of the utmost importance. The majority of cases where a digital inspection is being helded, people tend to think that those technological processes can only be made by a BIM expert or a very qualified data capture specialist. In fact:

- The inspection was performed by the site manager, and the system found the item just 5% within tolerance of the model. Thus, all the point cloud is in red representing the installed element distance from the model

- The alignment of the water pipes inspected has been confirmed 8 time faster than in traditional review methods

- The pipe is 10.05 ft tall, 3 in outside the tolerance of the planned element

Conclusion

The client verified the quality control of water pipes installation of the plant under construction. The general result was good, finding a single element out of tolerance. Even so, the deviated pipe was higher than it should have been (9,8 ft high), and this not only implied extra costs of qualified personnel, said error also implies extra hours for the architect to update the BIM model.

Do you want access to the full cases in PDF?

STRUCTURAL ELEMENTS LEVELING INSPECTION

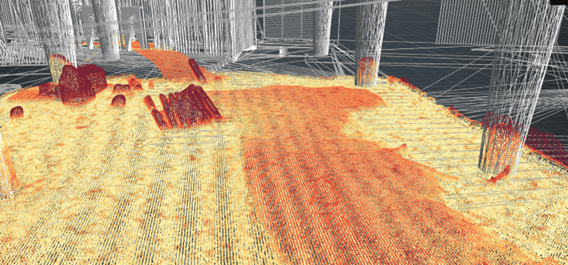

Correct leveling of elements in the construction process requires many hours of work by highly qualified personnel, representing a high cost of multiple revisions, before and after finding any deviation.

SITE-CAST ELEMENTS INSPECTION

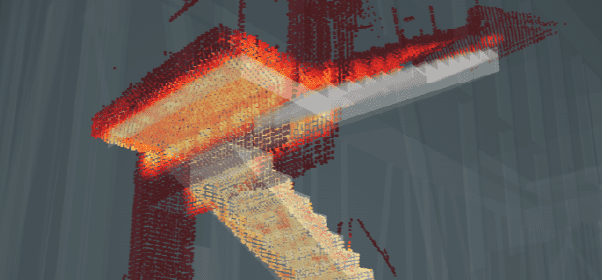

Errors when pouring concrete in the structural phase of a project can represent high rework costs that can be prevented with the use of technological tools.

PREFABRICATED CURTAIN WALL INSTALLMENT

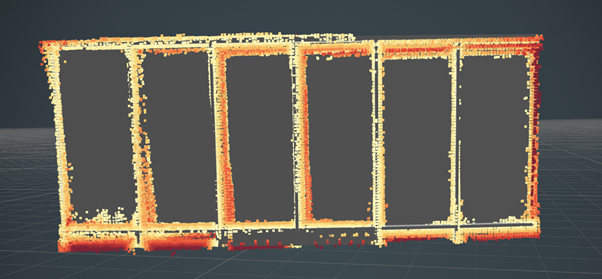

When using prefabricated modules for construction the Innovative building designs may represent cost overruns if the prefabricated modules are not correctly placed.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.