PREFABRICATED WALL INSTALLMENT

CHECKTOBUILD & ACERTA STORY OF SUCCESS

Time to take

decisions

From when the manager went to site to take the point cloud until available results

Costs saved

Estimated cost savings of rework to correct all 1100 modules, including crane cost, crane operator and 2 installers per h in case all were deviated. $284 per module

Increase in

productivity

Estimated percentage of savings in carrying out the inspection

About the project

Location: Madrid, Spain.

Industry: Office building

Work phase: Above Ground – Structure

Data capture method: iPad Pro (3D Scanner App)

Size: 232737.27 ft2

Project value: $16.5M

The problem

When using prefabricated modules for construction, an innovative building designs may represent cost overruns if the prefabricated modules are not correctly placed. In this specific project, adaptation of curved geometry to the model represented a constant concern for the owner, besides verticality of the modules throughout all the facade.

Operation process & scope

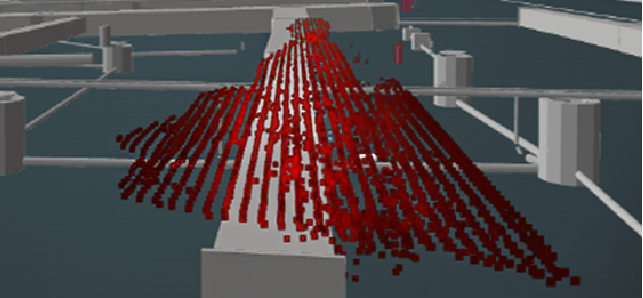

To address the client concerns and avoid unforeseen budget expenses the executed inspectión required multiple captures of the facade to check all the curtain wall. The site-manager seeked to:

1. Execute the inspection with models from an alternative data capture application to define if it offers best results for processing with CHECKTOBUILD

2. Upload models (BIM & POINT CLOUD) to execute inspection from an iPad

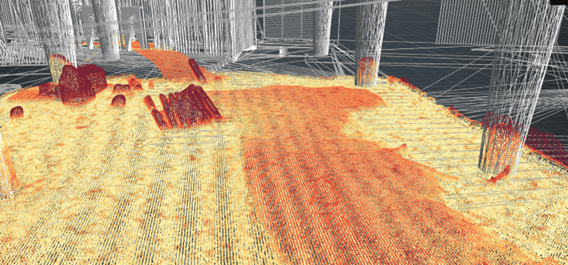

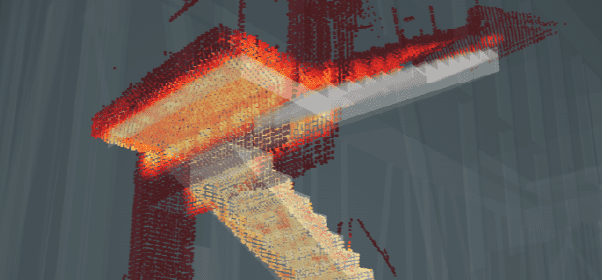

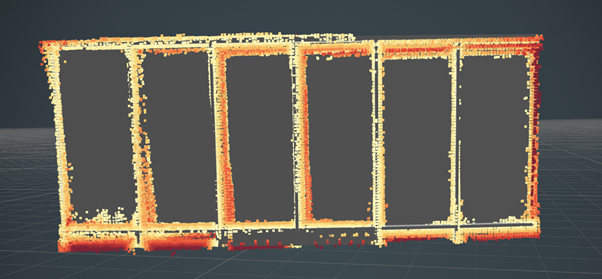

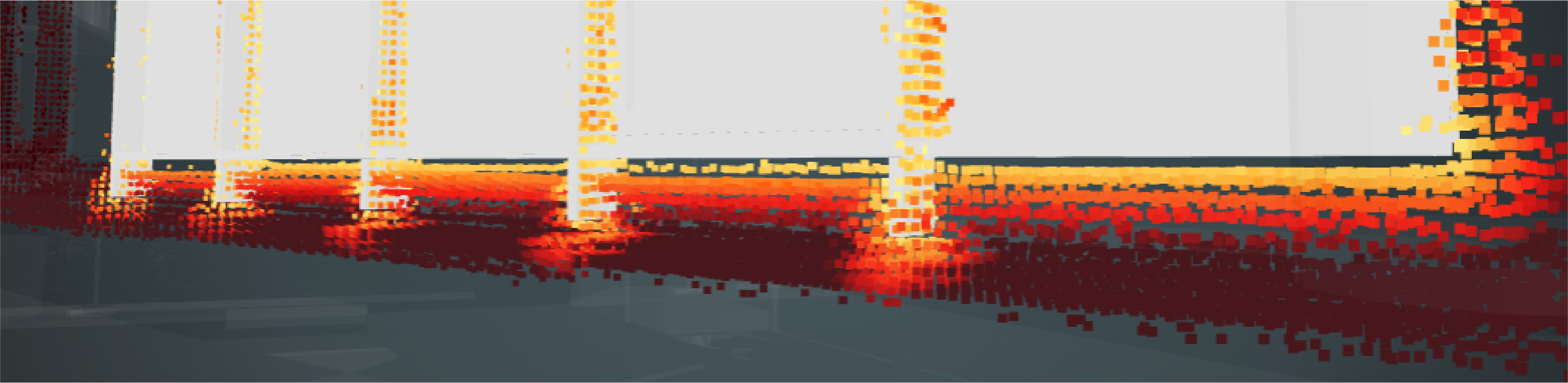

3. After having results, activate the heat map on the point cloud to highlight the deviated or missing elements

4. Share the inspection to the stakeholders

RESULTS

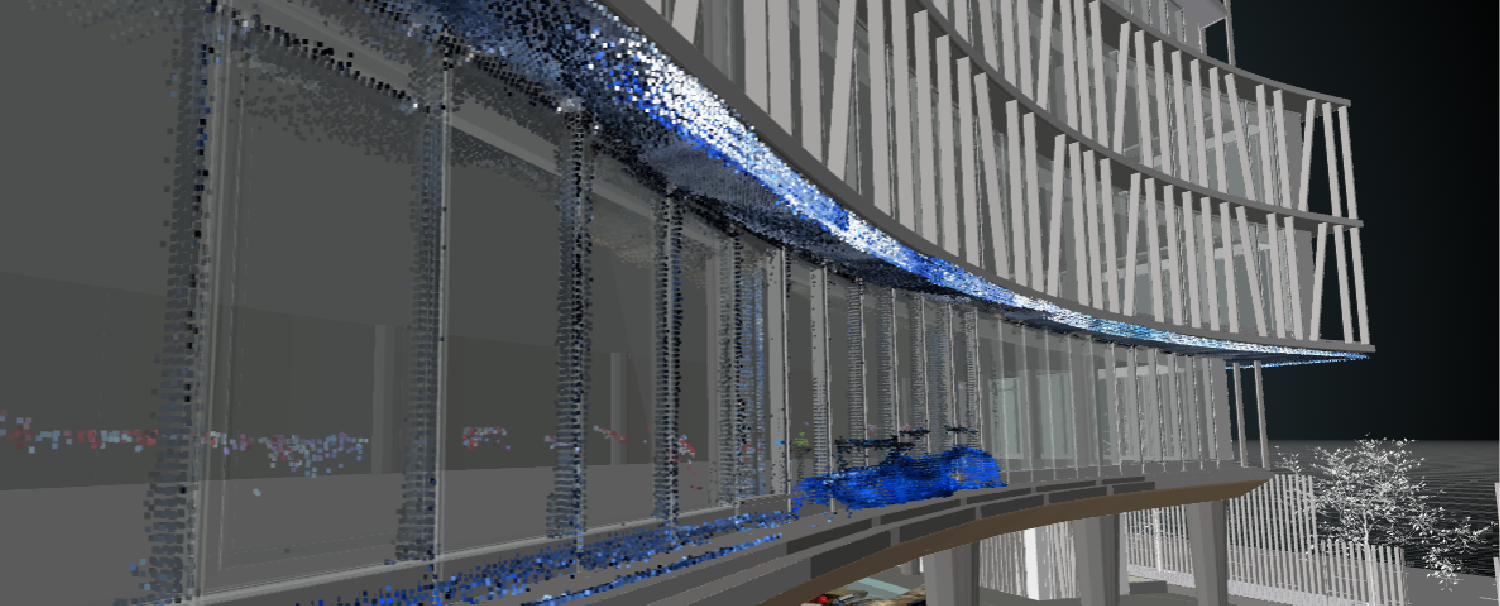

As the most suitable data capture technique for the client was through applications on an iPad, the inspection was processed with more than one point cloud against the BIM model, it showed:

- All modules are properly aligned, reaching a 92% in tolerance within the model

- In red color can be seen the skirting-boards that have not yet been installed and a mesh present in the cloud that does not match the model

- Complete facade, 110ft2, adapted smoothly to the curve geometry of the building

Conclusion

By doing the inspection the manager discovered that the alignment of the prefabricated modules was correctly installed. Whatsmore, the results allowed us to notice the missing elements that were part of the final finishes of the curtain wall, which means that although the modules are located in the right angle and position, the progress of the element is not 100% complete.

Do you want access to the full cases in PDF?

STRUCTURAL ELEMENTS LEVELING INSPECTION

Correct leveling of elements in the construction process requires many hours of work by highly qualified personnel, representing a high cost of multiple revisions, before and after finding any deviation.

SITE-CAST ELEMENTS INSPECTION

Errors when pouring concrete in the structural phase of a project can represent high rework costs that can be prevented with the use of technological tools.

WATER PIPES INSTALLATION INSPECTION

Pipe installation requires a post review to verify proper placement. To guarantee the precise level of these elements, will represent the fluid performance of the entire aqueduct and sewage system.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.