STRUCTURAL ELEMENTS LEVELING

CHECKTOBUILD & ACERTA STORY OF SUCCESS

Time to take

decisions

From when the manager went to site to take the point cloud until available results

Delayed

payment

Lack of payment for not

accomplishing tolerances

Time saved

Estimated after subtract spent hours on the same inspection with traditional methods

About the project

Location: Madrid, Spain.

Industry: Office building

Work phase: Above Ground – Structure

Data capture method: iPad Pro (Sitescape)

Size: 232737.27 ft2

Project value: $16.5M

The problem

Correct leveling of elements in the construction process requires many hours of work by highly

qualified personnel, representing a high cost of multiple revisions, before and after finding any

deviation.

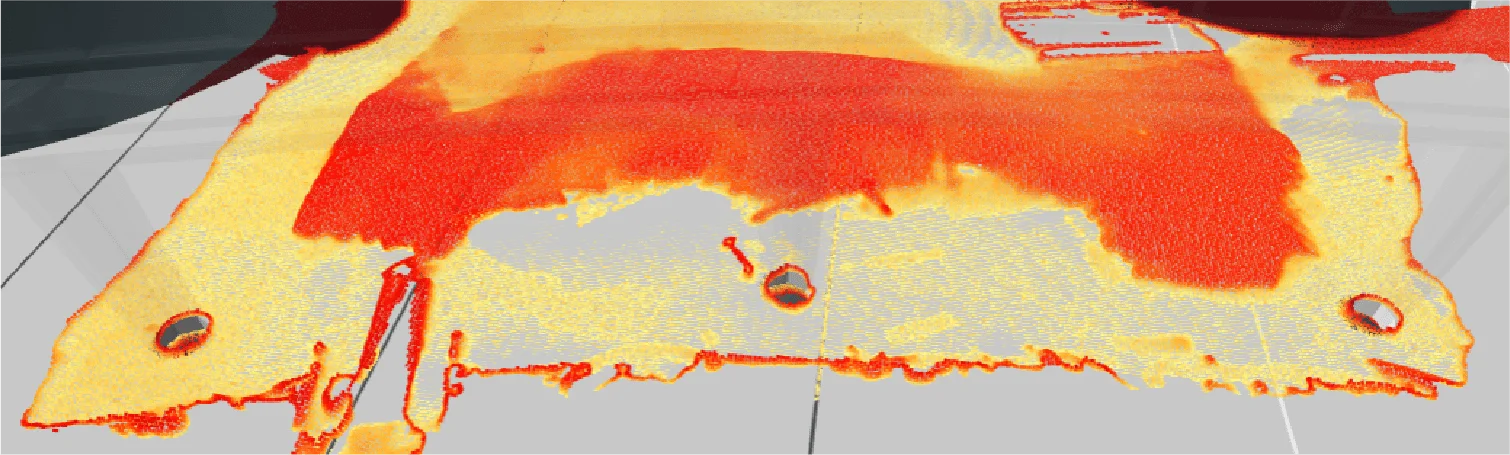

Following the construction of this structure, the client observed an area where water didn’t flow as intended. Recognizing the safety implications, it became imperative to assess whether there were any floor deformations beyond the structural joints

Operation process & scope

The inspection was executed by the site-manager with point clouds taken by the client with a LIDAR camera, improving in the use of data capturing techniques through a more affordable hardware compatible with C2B Platform. Only one tool was required to:

1. Implement the use of different data capture techniques to prove C2B Platform versatility

2. Upload models (BIM & POINT CLOUD) to execute inspection from an iPad

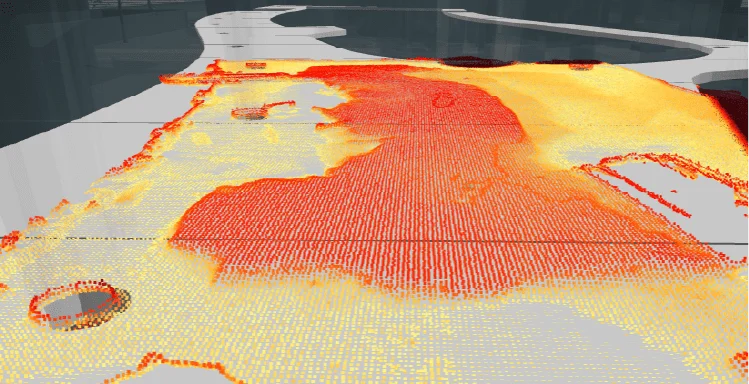

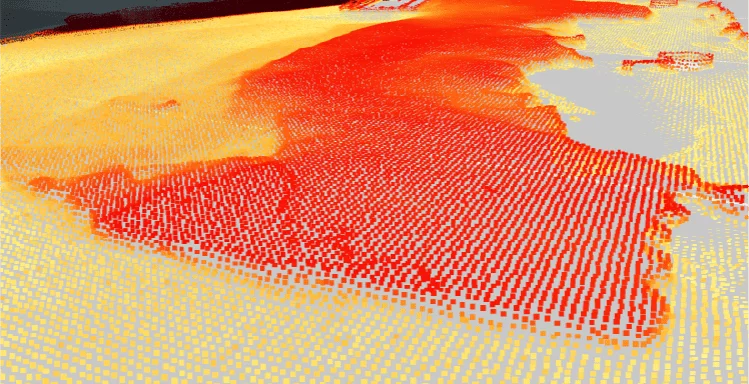

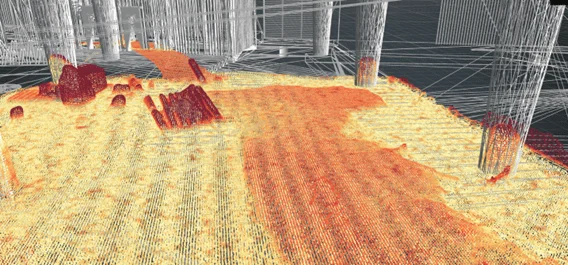

3. After having results, zoom in the deviated element and activate the heat map on the point cloud to highlight the level difference

4. Making decision to solve the leveling and share the inspection to the involved stakeholders in record time

RESULTS

Upon quick inspection through the C2B PLATFORM it was clear that there was a discrepancy in several areas. But the most critical deviation was observed in the flatness of the floor:

- An area of 30ft2 is uneven and causes accumulation of water

- The deviated area has only 54% inside planned tolerance

- The responsible obtained results 90% faster to make decisions

Conclusion

The client was in the early stages of implementing new inspection techniques, therefore, a tradicional topography inspection was requested as well to compare the accuracy of the results obtained by C2B Platform. Since the result provided by the surveyor took so long, the response time was delayed and the error could not be mitigated until a week later (Although C2B got the results 4 days earlier). Negatively impacting payment terms.

Do you want access to the full cases in PDF?

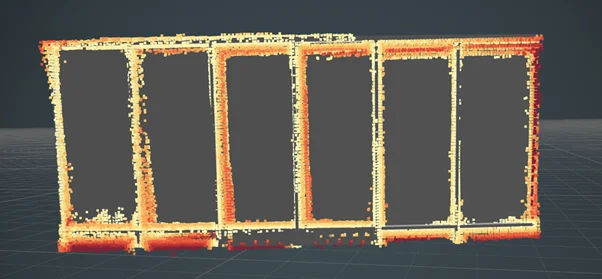

PREFABRICATED CURTAIN WALL INSTALLMENT

When using prefabricated modules for construction the Innovative building designs may represent cost overruns if the prefabricated modules are not correctly placed.

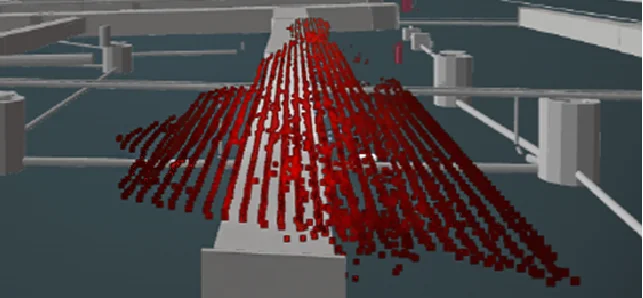

SITE-CAST ELEMENTS INSPECTION

Errors when pouring concrete in the structural phase of a project can represent high rework costs that can be prevented with the use of technological tools.

WATER PIPES INSTALLATION INSPECTION

Pipe installation requires a post review to verify proper placement. To guarantee the precise level of these elements, will represent the fluid performance of the entire aqueduct and sewage system.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.

Customer Support

If you’re currently using our solution and can’t locate the answer to your question in the Questions and Answers section, please reach out to our technical support.

Rest assured, providing a speedy resolution to your inquiry is of utmost importance to us as we continuously strive to enhance your customer experience.